Intelligent Warehouse Automation for reliable identification of 2,500 Tray Variants

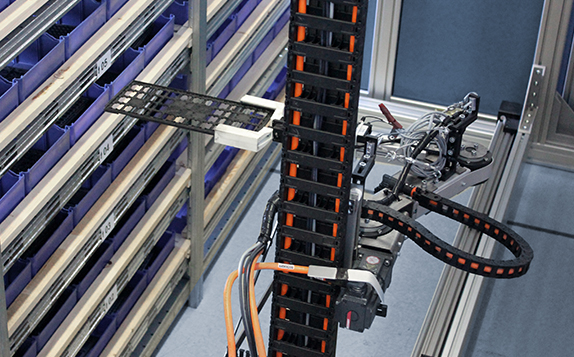

Matrium GmbH is a full-range service provider in the fields of logistics, purchasing and customs. With the help of STEMMER IMAGING, the company has developed an automated logistics system to sort JEDEC trays for a customer in the electronics industry. Up to 2,500 different tray variants can be reliably distinguished using machine vision before being placed in their allotted compartments by a robot.

The task

Develop an inspection system to reliably distinguish between different variants of JEDEC trays serving as transport containers for electronic components.

The solution

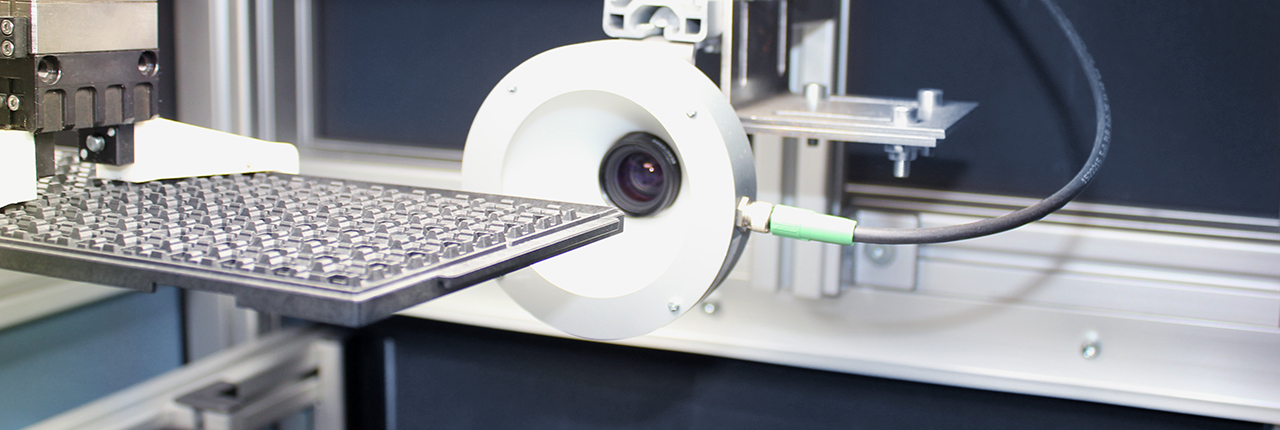

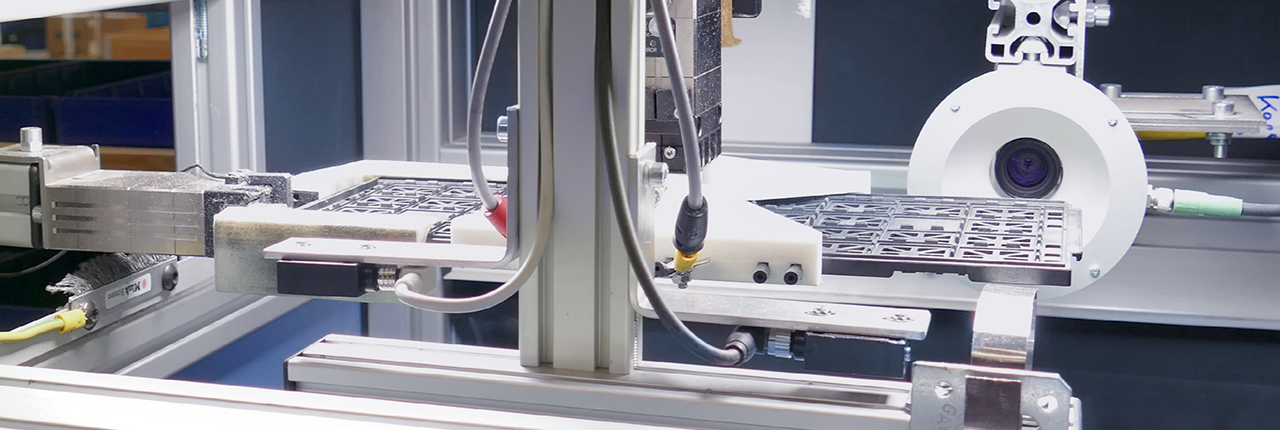

The machine vision system developed by STEMMER IMAGING is equipped with three high-performance cameras to ensure reliable detection of the trays and uses the first images to verify that the brightness regulation for final inspection is optimally matched to the colour and material composition of the trays.

In addition, STEMMER IMAGING's CVB Polimago imaging tool enables the reliable training of patterns within a minimum of time.

Machine vision ensures stable and fully automated sorting

A specially designed gripper takes the top tray from a stack and positions it in front of the three cameras of the integrated machine vision system. The cameras capture images from above and from the side and send the image data to the system's industrial PC. Since the non-uniform material composition, colouring and mattness of the trays cause different reflections, the first images of each tray are evaluated as a histogram, whose results were then used to regulate the brightness for the following captures.

In this way, images with a medium grey-scale value are achieved for each object creating opimum conditions for the subsequent image evaluation. In total, up to six images are captured per camera - which is not critical in terms of time, as up to five electrical measurements of the tray surface resistance have to be carried out in parallel to the image capture and recognition.

„With around 2,500 tray variants it was important to us to keep the programming work to a minimum. CVB Polimago saves us a lot of time in the training phase. All in all, the support from STEMMER IMAGING was an enormous help to us in implementing the system quickly and achieving reliable sorting results."

Martin Eikel, IT Manager at Matrium